Aerodynamics in Volkswagen Race Cars

Aerodynamics plays a crucial role in the performance of racing vehicles, and Volkswagen (VW) has consistently been at the forefront of these innovations. The ability to minimize drag and maximize downforce is essential for achieving high speeds and optimal handling on the track. Through advanced engineering and cutting-edge technologies, VW has redefined the standards of aerodynamic efficiency in motorsport.

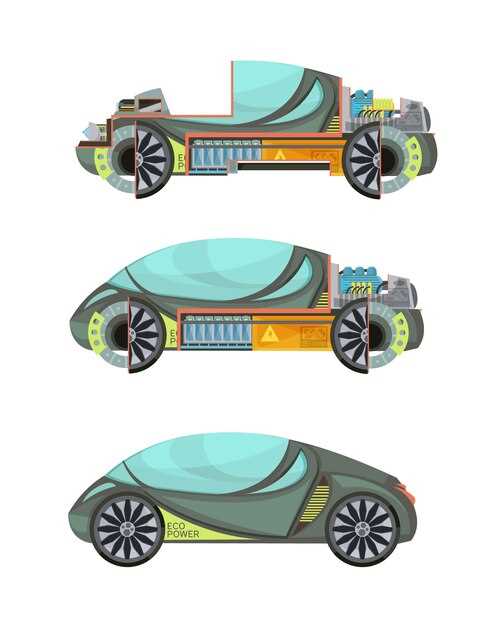

In recent years, VW has implemented a range of innovative aerodynamic features in its racing vehicles, aimed at enhancing both speed and stability. These advancements include sculpted body designs, strategic wing placements, and the use of lightweight materials that not only improve performance but also ensure compliance with rigorous racing regulations. Such meticulous attention to aerodynamics reflects VW’s commitment to excellence and competitiveness in the fast-paced world of racing.

As aerodynamics continues to evolve, VW remains a leader in integrating new technologies into their racing portfolio. The use of computational fluid dynamics (CFD) simulations and wind tunnel testing has allowed VW engineers to refine their designs to unprecedented levels of precision. This dedication to innovation not only helps VW excel on the race track but also influences the development of future commercial vehicles, paving the way for a new generation of automotive advancements that prioritize aerodynamics for enhanced efficiency and performance.

Maximizing Downforce Through Design Features in VW Racing Cars

In the world of motorsport, aerodynamics plays a crucial role in enhancing vehicle performance. Volkswagen (VW) racing cars are designed with a keen focus on maximizing downforce, which is essential for maintaining traction at high speeds. By optimizing various design features, VW engineers ensure that their racing vehicles achieve superior aerodynamic efficiency.

One of the primary elements contributing to downforce is the front splitter. This component helps to redirect airflow around the vehicle, creating a pressure differential that pushes the car down onto the track. Additionally, VW incorporates adjustable splitters in some models, allowing for fine-tuning based on specific track conditions.

The use of a functional rear wing is another critical feature in VW racing cars. These wings are meticulously designed to maximize downforce while minimizing drag. By experimenting with different shapes and angles, VW engineers achieve an ideal balance that enhances cornering capabilities without compromising overall speed.

Moreover, the integration of vortex generators on various surfaces creates controlled turbulence, which helps energize the airflow over the car’s body. This technique reduces drag and increases downforce, crucial for high-speed track performance. Combined with a sleek chassis design, these aerodynamic elements work in harmony to improve the vehicle’s grip and stability.

VW also utilizes lightweight materials in the construction of its racing vehicles. This not only improves acceleration and handling but also allows for better distribution of aerodynamic elements without adding excess weight. The combination of lightweight construction and optimized aerodynamics creates a formidable racing platform.

In conclusion, maximizing downforce in VW racing cars is achieved through a strategic interplay of aerodynamic features, including front splitters, rear wings, vortex generators, and lightweight materials. These design innovations showcase Volkswagen’s commitment to excellence in motorsport, ensuring that their vehicles remain competitive on both the track and the road.

Impact of Material Choices on Aerodynamic Performance in Volkswagen Motorsports

The selection of materials plays a crucial role in enhancing aerodynamic performance in Volkswagen (VW) racing vehicles. By integrating advanced materials, VW can optimize weight, strength, and efficiency, directly affecting the car’s aerodynamics.

Lightweight Materials are increasingly used in racing, where every gram counts. Carbon fiber and aluminum alloys provide significant weight reduction compared to traditional steel. A lighter vehicle can achieve higher speeds and better acceleration, crucial for competitive motorsports. Reducing mass also allows for improved handling, as the center of gravity shifts and responsiveness increases.

Aerodynamic Shapes are refined through selecting materials that allow for complex designs. High-performance plastics and composites enable the creation of airfoils and body shapes that minimize drag while maximizing downforce. This combination ensures that VW vehicles maintain stability and control at high speeds, which is essential for track performance.

Thermal Management is another aspect influenced by material choices. Advanced ceramics and heat-resistant alloys can withstand extreme temperatures generated during high-speed races. Effective thermal management ensures that essential components, like the engine and brakes, remain at optimal operating temperatures, maintaining performance and reliability.

Durability of materials impacts long-term performance. VW uses materials that resist wear and fatigue, ensuring that aerodynamic components can endure the rigors of racing. Materials that retain structural integrity under stress contribute to consistent performance throughout a race, allowing engineers to fine-tune aerodynamics without frequent replacements.

By making strategic material choices, Volkswagen enhances the aerodynamic capabilities of its racing vehicles, solidifying its reputation in motorsports. Each element, from lightweight composites to heat-resistant alloys, contributes to an overall design that prioritizes performance, efficiency, and competitiveness on the track.

Real-World Applications of Wind Tunnel Testing in VW Racing Development

Volkswagen has long been at the forefront of automotive innovation, particularly in the realm of racing where aerodynamics plays a crucial role in performance. Wind tunnel testing is an essential component of VW’s racing vehicle development, allowing engineers to simulate real-world conditions and optimize vehicle designs for maximum efficiency and speed.

The primary application of wind tunnel testing in VW racing development is to enhance downforce. By adjusting the shape and features of a vehicle, engineers can manipulate airflow to create increased downforce, which is vital for maintaining traction at high speeds. During tests, various models are subjected to airflow patterns, enabling the team to analyze how different aerodynamics components–such as spoilers, diffusers, and body contours–affect the car’s stability and grip on the track.

Another significant aspect of wind tunnel testing involves reducing drag. By fine-tuning the vehicle’s aerodynamics, VW can decrease drag coefficients, leading to improved acceleration and top speed. This balance between downforce and drag is critical, as too much downforce can lead to increased drag, which would negate the advantages gained on straights. Engineers employ sophisticated software to visualize airflow and identify design changes that can enhance performance without sacrificing aerodynamic efficiency.

Moreover, real-time data collected during wind tunnel tests influences the development of various racing technologies at Volkswagen. The insights gained help engineers make informed decisions about materials, structural integrity, and component placement. These innovations not only apply to racing but also trickle down into production vehicles, enhancing the overall performance of VW cars on the road.

Ultimately, wind tunnel testing is a cornerstone of Volkswagen’s commitment to racing excellence. By marrying theoretical aerodynamics with practical testing, VW continues to push the boundaries of technology and competitiveness in motorsports, securing its reputation as a leader in automotive performance.